Pre-Testing In-House First Is Essential

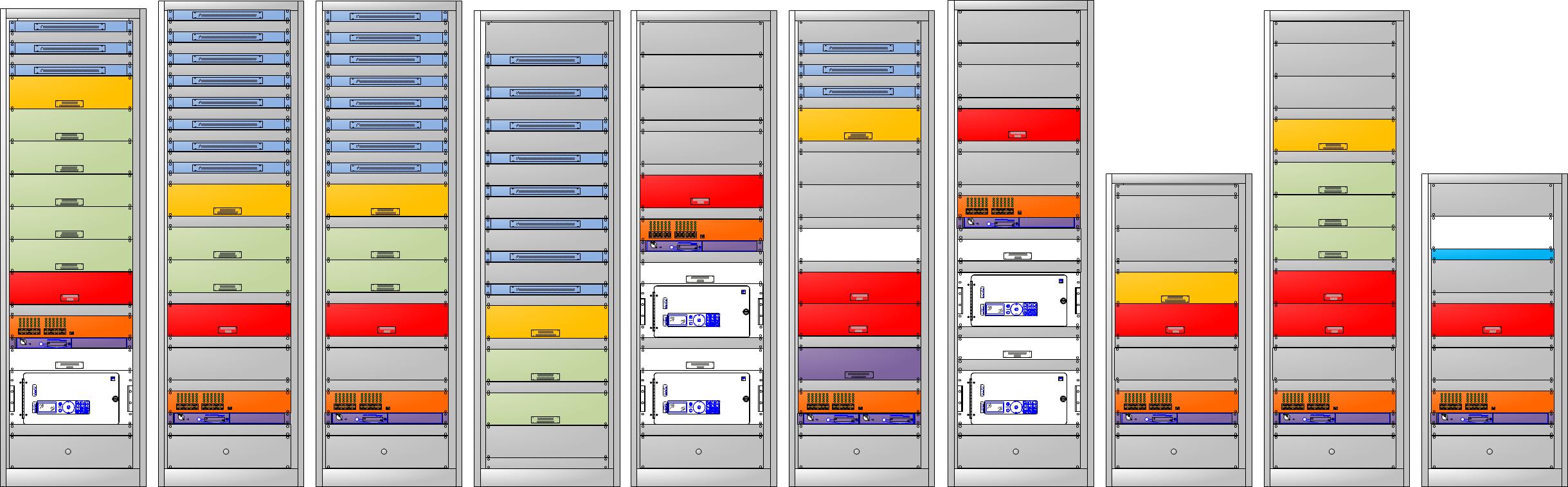

We’ve recently been working with a large multipurpose industrial Visitor Centre. There are 18 lighting control locations within their vast complex and each area will need its own lighting control data distribution rack. The solution is both complex but also future-proofed, and therefore has the potential to support 9,000 channels for lighting control.

We pre-configured all of the input and output gateways, control accessories and all interconnecting cables at our large warehouse in Buckinghamshire, to ensure the system was fully tested in-house first. By knowing that it works at our HQ, we won’t waste any time trying to solve problems onsite.

As if we needed any proof that this level of preparation is a great idea, on this project, we discovered that TWO off-the-shelf CAT5 patch leads were faulty! It would have been a nightmare to try and locate the potential problems these faulty leads could have caused over a vast multi-level site.

As we frequently integrate boxes from different manufacturers, putting the solution together first back at base insures we know the system is fully working and fully tested before we even leave to visit our client’s site. Interestingly, we still haven’t come across any other lighting control companies that go to these lengths in pretesting complex solutions offsite…